ECP2200H Preparative Pump

Preparative pump with flow-rate ranges of 0.001 - 250 ml/min, with very high pressure of up to 40 MPa at a flow of 100 ml/min.

| Image | PN | Wetted parts of pumping block | Request quote |

|---|---|---|---|

|

Image

|

PN

ACHEH00X

|

Wetted parts of pumping block

Stainless steel

|

Actions

|

|

Image

|

PN

ACHEHH0X

|

Wetted parts of pumping block

Hastelloy

|

Actions

|

|

Image

|

PN

ACHEHT0X

|

Wetted parts of pumping block

Titanium

|

Actions

|

- Description

- Parameters

- Files to download 4

This pump works as an isocratic pump and together with a gradient box also as a gradient pump.

These powerful and durable pumps are suitable for preparative applications in low- and high-pressure liquid chromatography across the chemical industry. They are designed with 2 pump heads connected in parallel with a piston diameter of 3/8”.

Many improvements make these pumps more reliable, including a new learning algorithm for pulsation suppression and a leakage sensor. New material versions have been added, beyond stainless steel A316L, also Hastelloy, titanium, and PEEK for biocompatible applications.

The pumps can operate in two modes, i.e., using constant pressure or using the newly added option of constant flow rate.

Gradient function: These pumps work as isocratic pumps, and, together with ECOM gradient boxes, they also work as gradient pumps. Gradient boxes ECB2005, ECB2005PC are equipped with a four-way gradient mixing valve and must be ordered together with the pump. These sophisticated units allow for achieving a precise low-pressure gradient, i.e. gradual changes of solvent composition by mixing up to four liquids at the pump‘s entry. The gradient profile can be defined via a computer or manually using a display and a keypad. Without the use of a gradient box, the pump works isocratically.

Customers can use the pistons‘ back-washing function while working, for example, with a buffered mobile phase.

Seals: All pumps are delivered with GFP (PTFE) seals by default. You can order the pumps with UHMW-PE seals, which are considered the optimal recommended choice.

Software support: The pumps are supported by ECOMAC and Clarity software.

Features and Benefits

• All models include a display and keyboard for manual control

• Precise low-pressure gradient mixing (when connected with a gradient module)

• Very good durability and reliability with proper maintenance

• Extended number of wetted material versions – not only stainless steel but also Hastelloy, titanium, and PEEK for biocompatible applications

• Piston back-washing function for work with buffered or aggressive mobile phases

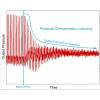

• New learning algorithm for pulsation suppression

• Integrated leakage sensor

• Custom pump modifications on request

This pump is equipped with the Pressure Compensation Learning algorithm. Thanks to this smart adaptive process, the pump regulates the rotation speed of the camshaft and measures its impact on pressure pulsation to minimize the output pulsation as much as possible. The algorithm, due to its adaptive capacity, is applicable for many combinations of pump working conditions (solvents, columns, etc.).

| Flow rate | 0.001 – 250 ml/min |

|---|---|

| Maximum operating pressure | 40 MPa (5800 psi,400 bar) up to 100 ml/min; 25 MPa (3626 psi) at 250 ml/min |

| Flow rate setting | 0.001 ml/min steps |

| Repeatability of flow rate adjusting | ± 0.5 % |

| Accuracy of flow rate setting | ± 2 % |

| Communication | RS232,Ethernet (LAN),USB,Remote digital I/O |

| Power supply | 100 240V 50/60Hz 250VA |

| Dimensions W x H x D | 280 x 135 x 498 mm (11.02 x 5.12 x 18.23 in) |

| Weight | 14.5 kg (32 lb) |

| Output capillary outer diameter | 1/8” |

| Upper pressure limit (MPa) | 1– 40 (5800PSI) |

| Precision of pressure measurement | ± 2% |

| Supported Gradient Box | ECB2005, ECB2005PC |

| Pressure Compensation Learning | yes |

| Filename | Type |

|---|---|

| Info-Piston_Seal_Materials-en | pdf (134,34 KB) |

| Info-ECP2050_2100_2200(H)_2300_pump-en | pdf (386,59 KB) |

| Manual-ECP2300_ECP2200_ECP2200H-en | pdf (3,39 MB) |

| Manual-ECP2300_ECP2200_ECP2200H-cz | pdf (3,11 MB) |

Accessories

Heating unit for pump heads 50 - 300 ml/min

The thermostat is designed for applications where liquids with a low melting point are pumped.

-250x170-4-0-0-ffffff.png)