Tri-clamp Flowcells for Low-temperature Applications

Tri-clamp Flowcells for Low-temperature Applications were designed for industrial or pilot-scale chromatography processes involving liquids at low temperatures. Thanks to their integrated blowing-out feature, they can overcome condensation that forms during low-temperature separation processes.

Related variants

| Image | PN | Name | Flange OD [mm] | Size ASME-BPE | Tube ID [mm] | Optical path length [mm] | Max Pressure [MPa/PSI] | Wetted Material | L [mm] | Request quote |

|---|---|---|---|---|---|---|---|---|---|---|

|

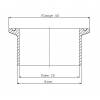

Image

|

PN

TF250400

|

Name

Blown-out TriClamp Flow-Cell SS Size 1/4" ID 4.57 mm

|

Flange OD [mm]

25.4

|

Size ASME-BPE

1/4"

|

Tube ID [mm]

4.57

|

Optical path length [mm]

0.1–4

|

Max Pressure [MPa/PSI]

30/4351

|

Wetted Material

SS 316L; PEEK MT; Sapphire

|

L [mm]

45

|

Actions

|

|

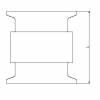

Image

|

PN

TF502200

|

Name

Blown-out TriClamp Flow-cell SS Size 1" ID 22.10 mm

|

Flange OD [mm]

50.5

|

Size ASME-BPE

1"

|

Tube ID [mm]

22.10

|

Optical path length [mm]

0.1–10

|

Max Pressure [MPa/PSI]

2/290

|

Wetted Material

SS 316L; FFKM; FEP; Quartz glass

|

L [mm]

52

|

Actions

|

|

Image

|

PN

TF503400

|

Name

Blown-out TriClamp Flow-cell SS Size 1.5" ID 34.80 mm

|

Flange OD [mm]

50.5

|

Size ASME-BPE

1.5"

|

Tube ID [mm]

34.80

|

Optical path length [mm]

0.1–10

|

Max Pressure [MPa/PSI]

2/290

|

Wetted Material

SS 316L; FFKM; FEP; Quartz glass

|

L [mm]

52

|

Actions

|

|

Image

|

PN

TF644700

|

Name

Blown-out TriClamp Flow-cell SS Size 2" ID 47.50 mm

|

Flange OD [mm]

64.0

|

Size ASME-BPE

2"

|

Tube ID [mm]

47.50

|

Optical path length [mm]

0.1–10

|

Max Pressure [MPa/PSI]

2/290

|

Wetted Material

SS 316L; FFKM; FEP; Quartz glass

|

L [mm]

79,4

|

Actions

|

- Description

Tri-clamp Flowcells for Low-temperature Applications are used for analyzing and monitoring the absorbance of cold liquids passing through the cell at temperatures where UV light is led from the detector and back using an SMA 905 connector and optical-fiber cables.

Pressure resistance: The cell is designed to withstand a maximum operating pressure of 30 MPa (4351 PSI) or 2 MPa (290 PSI) according to cell size.

Optical path length: Different optical path lengths are available: from 0.05 mm to 2, 4, 5, and 10 mm, according to the cell size.

Quality of the surface: The internal flow-through hole of the cell is characterized by its high-quality processed surface. Its internal surface quality value is less than Ra 0.4 µm. On request, the cell can be electro-polished and passivated.

Wetted Materials: Are 316L stainless steel body, a sapphire window, and an inner insert made of PEEK MT or Quartz window with FFKM and FEP sealing. On request, the cell body can be made from Hastelloy.

Features and Benefits

• Resistant to high pressures 30 MPa (4351 PSI) or 2 MPa (290 PSI)

• Elimination of dead volume

• Good rinsing without cross-contamination of the sample

• Compliant with USP Class VI requirements

• Wide range of optical path length options

• Compatible with ECOM external TOY detectors

• Inspection Certificate EN 3.1

• Flow cells of our production are designed following the ASME-BPE (Bioprocessing Equipment) standard. This globally recognized standard ensures that equipment meets the stringent hygiene and performance criteria required in industries such as biotechnology, pharmaceuticals, and food processing. Following these requirements, our flow cells provide exceptional cleanliness, reliability, and compliance with critical bioprocessing specifications.